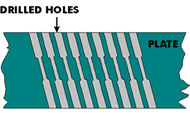

The following projects were manufactured by contouring and drilling etc. As with surfacing, geometry is either transferred to or created in Mastercam (our Computer Aided Manufacturing software). Then tooling is assigned to the contours and holes to produce code for the CNC Milling Centres.

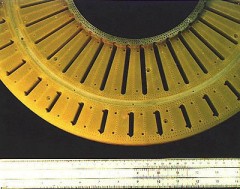

Sun Dial

Presented to Alois (Louis) Anton Raffler commemorating 30 years of outstanding service.

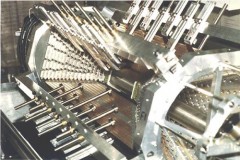

A.R.G.U.S. (A Russian German United States Swedish experiment)

This precision detector was manufactured and assembled at the Science Technology Centre. In particular interest to the CNC Section are the end cones which were manufactured on our Mitsui Seiki milling centre.