- Additive Manufacturing

- Advanced Aerodynamics

- Advanced Design and Design Configuration

- Assembly

- Avionics

- Control Laws

- Dynamics

- Loads

- Master-Lines and Mass Properties

- Multiscale Design Optimization (MSDO)

- Performance

- Structure and Stress

- Systems

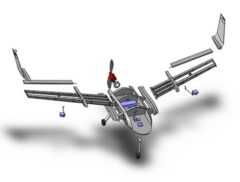

The Peregrine 1 Unmanned Aerial Vehicles (UAVs) are developed by a multidisciplinary group of students, from engineering streams such as aerodynamics, aero-structures, space systems and mechanical.

Additive Manufacturing

The Additive Manufacturing team is responsible for coordinating and conducting the additive manufacturing process from start to finish. This means working with cutting edge and top of the line equipment such as the Modix 120X 3D printer and NylonX carbon fiber filament.

Previous members of the team have developed protocols and procedures to optimize print processes, and the team’s objective for this year is to start manufacturing UAV components. In addition, the aim is to define manufacturing constraints, refine and calibrate print settings, and develop a compliance matrix by printing tensile testing specimens for testing. This will allow the team to define the orthotropic properties of NylonX with a given set of print parameters and use software such as Digimat to optimize part performance. Finally, the additive manufacturing team is responsible for continued upgrades to the printing equipment, outsourcing print tasks to private companies when they exceed our printing capabilities and coordinating with the Master-Lines, Stress and Assembly teams for final production.

Advanced Aerodynamics

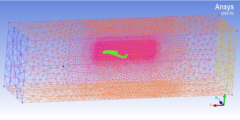

The role of the Advanced Aerodynamics team within the Peregrine project is to study the aerodynamics of the UAV. This is done by performing a Computational Fluid Dynamics (CFD) analysis on the UAV using ANSYS Fluent. From the CFD analysis results, the key aerodynamic parameters can be provided to the dynamics, stress and performance teams. Examples of parameters are the lift coefficient, the drag coefficient and the pitching moment for the aircraft. Furthermore, this analysis can be used to optimize the shape of the UAV to improve its aerodynamics.

The advanced aerodynamics team is also responsible for verifying the integrity of its CFD results. This will be done by cross-checking the results with data from wind tunnel tests. This year, the aerodynamics team plans on refining these simulations and studying the impact of control surfaces and landing gear on the flight of the UAV.

Advanced Design and Design Configuration

The Advanced Design team is tasked with modifying and upgrading the clean sheet design for the second iteration of the UAV, Peregrine II. Peregrine II is a larger and more capable version of the Peregrine I UAV.

The advanced design team is responsible for verifying the stability of the existing Peregrine II model using the Computational Fluid Dynamics (CFD) software ANSYS Fluent. The team will analyze the pressure distribution over the surface of the aircraft to ensure it will be stable throughout its flight. This will allow them to design and size the aircraft to meet its speed and performance goals.

Assembly

The Assembly team defines the strategies that will be used to attach the various components during the assembly process. It is also crucial that all of the joints be analyzed to ensure that they will be able to withstand all of the loads placed on them. The physical assembly must be as close as possible to the design in order for all of the calculations to remain accurate. The assembly team is also responsible for incorporating other relevant systems such as avionics into the body of the aircraft.

During this year, the assembly team plans to assemble all the 3D printed components of the aircraft and install the remaining systems so that the Peregrine I can begin flight testing.

Avionics

The Avionics team is responsible for developing all the electrical components, implementing autonomous flight using flight control software and setting up the ground control station for the Peregrine I. They will use the PX4 flight control software to implement autonomous flight and optimize this firmware for the single-rotor blended wing body design of the UAV. This will involve creating a new airframe model and mixer file for the software specific to the Peregrine I. The ground control station that will be used for this year is called QGroundControl. This ground control station will allow the team to develop flight plans, change flight parameters and control the UAV through the flight hardware.

The main flight hardware that will be used for the Peregrine I is the Pixhawk Cube, an autopilot hardware compatible with the PX4 hardware. All of the components on the aircraft will communicate through the Pixhawk. The avionics team is also responsible for flight testing of the Peregrine I. In preparation for flight testing the UAV, they will perform flight simulations in the Gazebo simulation and test prototype models to ensure the autopilot and avionics are functioning properly. The aim of the avionics team is to achieve autonomous short takeoff and landing (STOL) this year.

Control Laws

The duty of the Control Laws team is to oversee the control of the aircraft and the analysis of the Peregrine I’s stability. Autonomous flight is an important aspect of most UAVs; accordingly, the development of an autonomous flight system is the key target for the control law team. During the past years, the longitudinal and lateral state space models were developed and implemented into a PID controller. This year, the team aims combine these controllers and develop a custom Linear-Quadratic Regulator (LQR) controller to better account for dynamic couplings present with the BWB configuration.

The team will also conduct sensitivity studies for the updated model, tune PID gains using fly-by-wire techniques during test flights and port their custom Simulink model for the control system onto the UAV hardware by collaborating with the avionics team.

Dynamics

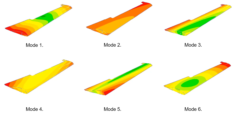

The Dynamics team is responsible for modal and flutter analysis (Solution 103 and 145, respectively in MSC NASTRAN) of the Peregrine I. Modal analysis focuses on identifying the natural frequencies and the corresponding mode shapes of the aircraft in order to identify how the sections of the aircraft will experience stress, strain and deformation. If the aircraft experiences vibration near one of its natural frequencies, it may lead to structural failure.

Flutter analysis focuses on the dynamic instability of the aircraft under aerodynamic, elastic and inertial forces. It is the continuous , self-sustaining vibration of portions of the aircraft which leads to failure. This analysis allows the flight envelope and the corresponding velocity-damping and velocity-frequency plot to be determined.

During 2021-2022, a preliminary modal and flutter analysis was conducted for the Peregrine I with VTOL capabilities. The focus for the 2024-2025 period is to update and refine the Peregrine I model and flutter analysis for the conventional flight configuration.

Loads

The Loads team is responsible for determining the structural loads acting on the Peregrine I during critical flight and landing conditions. They work closely with the Stress Engineering team to ensure that the airframe can withstand these forces and maintain structural integrity.

This year, the team is updating the load cases using MSC ADAMS, incorporating the latest aircraft geometry and mass properties. They will analyze the forces acting on the newly designed landing gear and examine hard landing scenarios, high-speed descent landings, and uneven terrain landings. Their findings will guide structural reinforcements and ensure safe operation under extreme conditions.

Master-Lines and Mass Properties

The Master-Lines & Mass-Properties team is responsible for developing the CAD model of the Peregrine I and ensuring proper weight distribution for flight stability and performance. Their work includes refining the aircraft’s outer mold line (OML) and providing mass property estimates such as center of gravity and moments of inertia.

This year, the team is transferring the existing CAD model from SolidWorks to CATIA while optimizing the blended wing body shape for improved aerodynamics. They are also working to integrate solar panels into the aircraft structure, balancing weight distribution to maintain stability. Additionally, they will analyze potential design changes to improve stiffness, reduce fuselage weight, and streamline components for manufacturability.

Multiscale Design Optimization (MSDO)

The MSDO team focuses on optimizing the Peregrine I’s structural components using advanced computational techniques. They aim to reduce weight while maintaining strength by integrating topological and lattice structures into the airframe design.

This year, the team is working in ALTAIR Hypermesh to refine optimization methods for key structural components. They will define new mass and stiffness distributions, support the Loads and Stress teams by providing updated designs, and coordinate with the Master-Lines team for CAD integration. Additionally, they will conduct optimization studies on the wing and fuselage, ensuring that the airframe is lightweight and structurally sound.

Performance

The Performance team is responsible for calculating how the aircraft will fly in all phases of flight: take-off, hover, cruise, glide, and landing. They are also responsible for propeller and motor analysis, finding the envelope in which the UAV can safely fly and determining the range of the aircraft.

For the 2024-2025 year, the performance team will use a new software APP. Aircraft performance parameters will shortly be calculated and optimized using DARCORP software program by the performance team. Three main sections form the app: the Aircraft Section, which holds records of specific aircraft data including weight, fuel capacity, and engine performance; the Performance Section, which determines significant values such as takeoff distances, climb rates, and fuel efficiency; and the Mission Profile Section, which predicts actual-world performance on the basis of the flight path, waypoints, and weather.

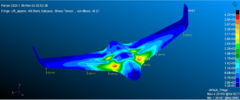

Structure and Stress

The Stress Engineering team is responsible for conducting structural analysis and optimization of the Peregrine I airframe. This involves developing a detailed finite element model (DFEM) and performing linear static stress analysis to determine whether the aircraft can withstand its maximum expected loads. The team also works to refine the airframe by reducing weight in less critical areas while maintaining structural integrity.

A key focus is the application of optimization techniques, including the integration of topological and lattice structures, to further minimize weight without compromising strength or stiffness. Additionally, the team ensures proper connectivity between components, reduces stress concentrations, and prepares structural elements for additive manufacturing. This year, their efforts will be directed at finalizing the DFEM for all major components, completing linear static analysis, and applying optimization methods across the airframe to enhance performance and manufacturability.

Systems

The Systems team is responsible for making sure all of the Peregrine I’s major components work together properly. Their work includes the design and analysis of powerplant integration, control surface actuation, and overall system functionality to enhance the UAV’s performance and reliability.

This year, the team is focused on implementing flexible solar panels into the wings to extend the aircraft’s operational endurance, optimizing power management for sustained flight. Additionally, they are refining the landing gear design to improve ground handling and durability. Key to the scientific objectives of the UAV is the mapping module, which will scan terrain with the NDVI spectrum to determine vegetation encroachment on power lines. Alongside these tasks, the team continues to work on ensuring proper integration of key systems, validating their functionality, and supporting the overall manufacturability of the UAV.