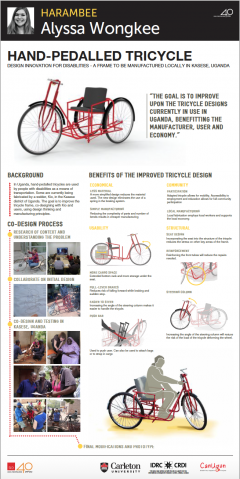

Before this project, wheelchair-tricycles were already in use in Uganda, some of them manufactured by local artisan welder, Kio, in partnership with Canadian-Ugandan not-for-profit CANUGAN. Fourth-year student Alyssa Wongkee saw the opportunity to improve the frame of the tricycle so as to make it more economical to produce, more user-friendly with more features, with an improved, more durable structural design.

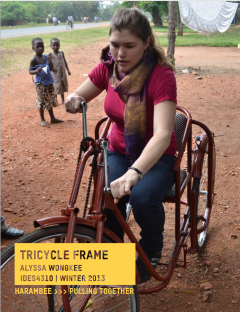

Alyssa worked with the local manufacturer, Kio, to design a new and improved prototype of a tricycle frame. Understanding the process by which Kio had been making the tricycles was a crucial part of Alyssa’s project, as she was then able to identify areas that could be improved upon.

By simplifying the design of the tricycle’s frame, Alyssa was able to eliminate the use of unnecessary materials and therefore reduce the cost of production. Her design included more cargo space for users, the incorporation of pull-lever brakes, a push-bar at the back so the chair could be pushed, or, so that the user could hang bags and carry additional cargo, and, made the tricycle easier to steer.

Alyssa’s new design, created in conjunction with Kio, improved the structural integrity of the tricycles so that less repairs would be needed. Overall, Alyssa worked to improve the mobility of tricycle users in the local Ugandan context.