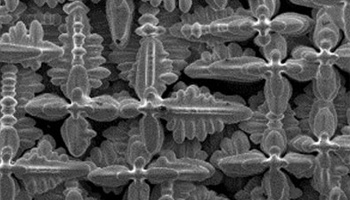

Carleton Aerospace researchers have access to a range of material testing facilities including servohydraulic test frames, an instrumented Instron Dynatup 8200 drop weight impact tower, TA Instruments differential scanning calorimeter (DSC) and thermogravimetric analyzer (TGA), and high temperature creep, fatigue and static testing.

This gives Carleton faculty and students the ability to study the behaviour of polymers, metals, composites, ceramics and hybrid materials under a wide range of testing conditions.

These testing facilities are supported by access to non-destructive imaging, metallographic and fracture analysis capabilities such as scanning electron microscopy, a Skyscan 1173 micro computed tomography, an Acoustocam i600 digital acoustic video camera, and optical microscopy and imaging facilities.

Driven by an increase in research activities involving composite materials and an influx in the use of these materials in the construction of aircraft, Carleton University has recently invested $300,000 in the development of a dedicated clean room for the manufacturing of composite parts using low-temperature-curing methods.

Additionally, Carleton’s Bridgman Furnace and Plasma Spray Coating Facility enables researchers to develop and test cutting-edge materials, composites and coatings. Primarily used to study materials for gas turbine engines, these facilities allow for fundamental material sciences to be studied and applied to real life challenges facing industry such as developing materials that can withstand extremely high levels of heat, pressure, and abrasion.

Facilities

Carleton Aerospace has several facilities purposed for research in this area:

- Laser Imaging Facility – Claire Samson

- MAE Structures Lab

- H. I. H. Saravanamuttoo Gas Turbine Laboratory

- Microelectronics Fabrication Facility

- Aerospace Materials Lab – Bridgman Furnace

- Plasma Spray Coating Facility