The Science Technology Centre (STC) recently worked with a team of engineering students from the University of Ottawa that are building a hypermile car – called the Supermileage Car – for an international competition. We spoke with Nicholas Fekete, a member of the engineering team, about the project and his experience with the Science Technology Centre.

Tell us a little about the competition you’re entering.

Nicholas: The name of the competition we are going to attend is called “Shell Eco-Marathon Americas”. Shell Eco-marathon Americas will be taking place at Sonoma Raceway in Sonoma, California from April 19 to 22, 2018. We are a team of about 20 engineering students, but about 12 of us will be going to the competition to compete against 15 teams in our category from other universities and high schools in America. However, the competition itself hosts around 100 teams to compete in other categories.

Shell Eco-marathon is one of the world’s leading energy efficiency competition programs. Students are challenged to design, build and test energy-efficient cars, pushing the boundaries of what is technically possible. Students take their designs to the track in the Mileage Challenge to see which vehicle can compete to go the farthest on the least amount of fuel.

Did you participate last year? How did you do?

Nicholas: Last year at the competition in Detroit, Michigan. Unfortunately, we couldn’t complete the required number of laps of the circuit because of technical issues. Therefore, we couldn’t have a mileage in for the competition.

What are you goals this year’s competition?

Nicholas: This year, our main goal is to get a mileage in with our new vehicle. We are designing and building a vehicle in less than a year. Last year, we competed in the prototype class, which consisted of a 3-wheel vehicle. This year, however, we are competing in the Urban Concept category, which means we needed to design a completely new vehicle. The main difference between the two are that the Urban Concept vehicle has 4 wheels instead of 3 like the prototype has. Basically, the Urban Concept vehicle resembles more a modern-day vehicle.

Why did you choose to work with STC?

Nicholas: I’d heard about STC from our team supervisor, Patrick Dumond, so I decided to go and see for myself how this facility could help us achieve our goals. After meeting with Graham and Steve, we decided to get our cross sections waterjet cut by the STC. Both are very welcoming and give great advice. Graham for example, who was doing the waterjet cutting of all the cross sections of the vehicle, put in a lot of heart into making it work for us. It made it seem like our project was also part of his project.

Can you walk us through the manufacturing process for the car body?

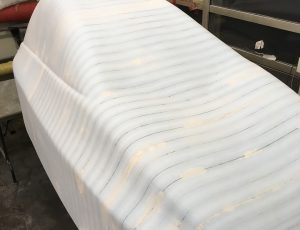

Nicholas: We first started with doing a CAD of the body with cross sectional drawing files every 2 inches of the vehicle for the STC to perform their waterjet cutting system. Once we acquired all the sections of the car, we applied adhesive between each sheet and glued them all together to make the complete shape of the body. Now the sanding starts. When doing cross sections of the vehicle, there’s lots of excess that must be sanded off to get the perfect shape we want.

Afterwards, we applied a layer of fiberglass to give it rigidity. We also needed to sand the excess epoxy that was left from our wet lay-up. Then, it was off to Whiticar Auto Body to get it to the absolute perfection. They did many coatings of high build surface primer with sanding in between each coating.

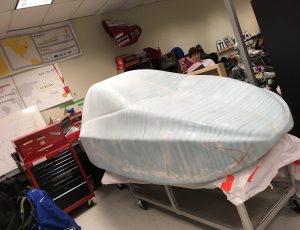

Once the body shop is done, it’s off to the composites workshop where all the composites will be done. What we’ve done so far was the male mold which is called the plug. The composites shop will be doing a final paint on the plug to allow them to do female plugs. The female mold is basically a negative shape of our plug, or more known as a shell. Afterwards, we will be vacuum infusing carbon fiber inside the shell to get the exact shape of the male plug that the body shop finished with smooth lines.

Would you work again with STC?

Nicholas: Although pricey for a university team, I would absolutely work with the STC again.

For more information about the Shell Eco-Marathon Americas competition, click here.