The CABER Lab’s recent introduction to the research community at Carleton University has given the team the opportunity to develop new testing apparatuses that enhance research and data collection. As the lab continues to grow, progress regarding testing development will be regularly updated on our website.

In partnership with CanmetENERGY Ottawa, an additional testing facility located in Bells Corners has been built to house large scale testing apparatuses which perform the bulk of testing for the team.

Large Scale Equipment:

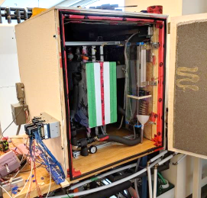

Guarded Hot Box

The Guarded Hot Box (GHB) is the single largest piece of equipment in CABER and is primarily used to accurately determine the overall effective thermal performance of complete wall assemblies. It is one of the largest guarded hot boxes in the world, capable of testing a sample area of up to 3 m wide and 6 m tall. The climate side can generate various climate conditions ranging from 55℃ to -35℃, while the interior metering side can be controlled from 15℃ to 30℃.

In addition to testing under standard conditions, transient conditions can be programmed into the chamber controls and different temperature cycles can be tested. To determine the impact of air infiltration on thermal performance, both sides of the wall assembly can be individually pressurized up to 1000 Pa above atmospheric conditions.

Although primarily designed for thermal testing, hygrothermal testing can also be conducted in the GHB. To achieve this, humidity can be controlled from 10% and 95% relative humidity when the chambers are above 4℃. The chamber also supports various instruments such as embedded relative humidity sensors, temperature sensors, and moisture sensors to measure the movement of heat, air and moisture through the assembly. Finally, a 22-kW infrared heating system has been developed to simulate solar heating of exterior façades and is used to evaluate the solar vapor drive in building envelope systems.

|

Pressurized Spray Rack (PSR)

This testing apparatus can be used interchangeably with test wall assemblies using the guarded hot box and focuses on measuring air and water leakage of an assembly. With 96 nozzles, the PSR can simulate up to 40 GPM of rain and a pressure of 1000 Pa with a goal to test air sealing methods and measure air leakage. After PSR testing, samples can be moved to the GHB for thermal testing, freeze/thaw testing, or testing the impact of solar heating on wet samples to determine if inward vapor drive is present.

Meteorological Monitoring

To determine the building envelope’s weather conditions, a meteorological station has been installed at the CABER facility in Bells Corners. Using a solar tracker, the weather station focuses on measuring the direct, indirect, and total horizontal radiation, as well as the incident radiation on a vertical surface in each of the four cardinal directions. The secondary focus measures precipitation with heated and driving rain gauges to determine the precipitation that strikes a surface. Other factors such as temperature, relative humidity, barometric pressure and wind conditions are also measured, recorded, and will be available to the public in the near future. For current inquiries about data, please contact Chris Baldwin or Brock Conley.

To determine the building envelope’s weather conditions, a meteorological station has been installed at the CABER facility in Bells Corners. Using a solar tracker, the weather station focuses on measuring the direct, indirect, and total horizontal radiation, as well as the incident radiation on a vertical surface in each of the four cardinal directions. The secondary focus measures precipitation with heated and driving rain gauges to determine the precipitation that strikes a surface. Other factors such as temperature, relative humidity, barometric pressure and wind conditions are also measured, recorded, and will be available to the public in the near future. For current inquiries about data, please contact Chris Baldwin or Brock Conley.

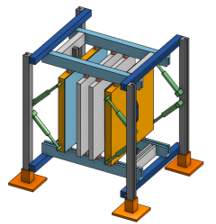

In-Situ Wall Openings

CABER is built with six 3 m x 3 m openings (four along the south façade, two along the west façade) which accommodates long term in-situ testing of both heat and moisture transfer within the assemblies over multiple years. Each opening is wired to host up to 64 sensors which are continuously monitored and recorded.

Additionally, active systems integrated into the building envelope can be tested within the southern facing openings. Lastly, the two southern openings are connected to 3 m x 3 m rooms on the inside of the facility which provide additional research on controlled interior conditions and occupant comfort.

Material Property Testing:

In addition to the large scale test apparatuses being designed and built in CABER to test large building envelope assemblies, a full suite of small scale systems have been built/purchased for use within CABER and are detailed below.

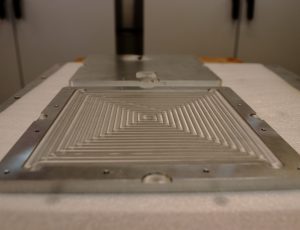

Guarded Hot Plate

The guarded hot plate is used to accurately measure the thermal conductivity of a material sample. It consists of two chilled plates, a hot plate, and the heat flow through the sample being tested. One unit is installed within the CABER lab at Carleton with a metering area of 200 mm x 200 mm, cold plates down to -15℃, and hot plates up to 65℃. The second unit within the CABER lab in Bells Corners has a metering area of 450 mm x 450 mm and is capable of cold plate temperatures down to -35℃.

Heat Flow Meter

Used to measure the heat capacity of a material, CABER has built a heat flow meter using two hot plates, which are preheated and then brought into contact with the sample material. The heat capacity can be determined by measuring the time required for the sample to increase in temperature.

Constant Temperature and Humidity Chambers

Two large constant temperature and humidity chambers have been installed within CABER and are used for two main purposes. The first is to artificially age materials at elevated temperature and humidity and when coupled with the guarded hot plates, the degradation in thermal performance can be determined. The second purpose is to determine the moisture permeance and conditioning of materials.

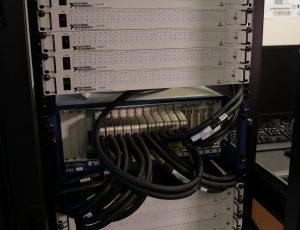

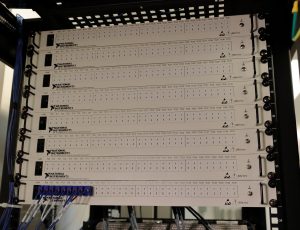

Data Acquisition:

CABER and SESL have large data acquisition systems allowing for vast amounts of data to be collected in real time. Sensors and data collected can range from miniscule resistance measurements for temperature readings to large voltage readings for power consumed.