Control Banding

What is Control Banding?

Control banding, or occupational exposure banding, is a systematic process using qualitative and quantitative hazard information to identify potential exposure ranges or categories.

Using the US NIOSH Occupational Exposure Banding (OEB) as the core backbone, EHS has created an internal banding approach. The control banding process ranks chemicals into health bands from least harmful (band A) to most harmful (band E) based on their toxicity and potential negative health effects.

Our control banding tool ranks the chemicals from Carleton’s chemical inventory system based on H-codes assigned by the Globally Harmonized System. However, H-codes do not include physical hazards such as reactivity, volatility, and dustiness. As a result, by adding this information, we progressed from a health banding approach to a more generalized hazard ranking system.

Control banding aims to provide an easy approach to handling hazards, and is often used to determine control measures when occupational exposure limits are unknown.

Risk Level-Based Management System

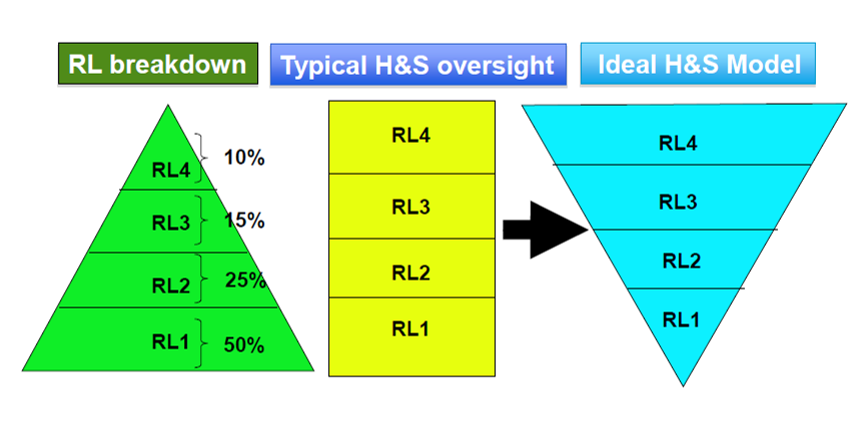

The risk level-based management system is an occupational exposure model that focuses on occupational safety, hygiene, and health resources on the highest-risk procedures at work.

The control banding system approach generates a tiered inventory of chemicals, where a chemical of least interest would be R1 and a chemical with the greatest interest would be R4.

Additionally, information such as operating temperature, frequency of use, engineering controls, administrative controls, and personal protective equipment will be collected from laboratory personnel. As more inputs are provided, a comprehensive risk banding inventory will be developed.

Therefore, each chemical could be assigned degrees of attention and resources based on where they fit in the banding process. In simpler terms, EHS professionals can focus on the more hazardous (higher risk level) materials to ensure an effective and proactive approach to exposure control.