Natalie Woerlen

Senior Lab Analyst

| Degrees: | B.Sc. (Biology & Biotechnology) |

When did you graduate from Carleton, and what program were you in

I took the Bachelor of Science, Biology & Biotechnology program and graduated in December, 2015.

Where do you work now, what is your position title, and when did you start?

I work at Greenfield Global Inc in Johnstown Ontario as a Senior Lab Analyst. I was hired in May, 2015 and have been there ever since. At our location in Johnstown we make alcohol, corn oil and distillers grains from corn. The corn we use is sourced from local farmers. Fuel, pharmaceutical, industrial and beverage grades of alcohol are produced through a process involving enzymatic breakdown of starch in the corn, fermentation with yeast to convert the sugars to alcohol and distillation to separate the alcohol out.

Can you give a general description of your position?

I work in the Quality Assurance department so our main tasks are to ensure all the lab equipment is working properly. We also conduct tests on all batches of the final product to ensure the quality is within customer specifications. When plant trials are going on we provide laboratory support. Each week we chair the technical team meeting to look over trends in the data and address problems in operations. We do quite a bit of data analysis on test results and also get the opportunity to install new methods for testing.

What does an average day for you involve?

I work 12 hour day shifts, 3 – 4 days/week. An average day usually starts off by running check standards on all our equipment to ensure accurate readings. Equipment that we use includes moisture analyzers, HPLCs, GCs, auto titrators, pH meters, DMA, FTIR, UV-Vis and solvent extraction units. If any of the equipment isn’t working it’s our job to troubleshoot or call technical support to fix it. We enter data from our fermentors and look at trends in process results to predict upsets. Since we don’t have the capability to test for everything onsite, we package and send samples out for third party testing. Teamwork is carried out with other departments to fulfill shipments on schedule. We are responsible for testing the product, giving the okay to release, generating the mix sheets and Certificate of Analysis. Some customers care about the odor and as such we set up an odor panel since the only way to detect some compounds is by smell because they are in the pbb concentration range. In the afternoons once the day-to-day tasks are completed, we occasionally have time for working on projects. These might include designing dashboards to visualize data, assisting with a trial, setting up new equipment, writing standard operating procedures or taking a course to increase our knowledge.

In the distillation section of the process.

As a student, were there experiences or opportunities that helped you get such a position. If so which ones?

One summer I got the opportunity to do research abroad, thanks to Dr. Shelley Hepworth, with funding from NSERC. This experience set me apart from other applicants. I tried hard and got good marks which showed promise and an openness to learn.

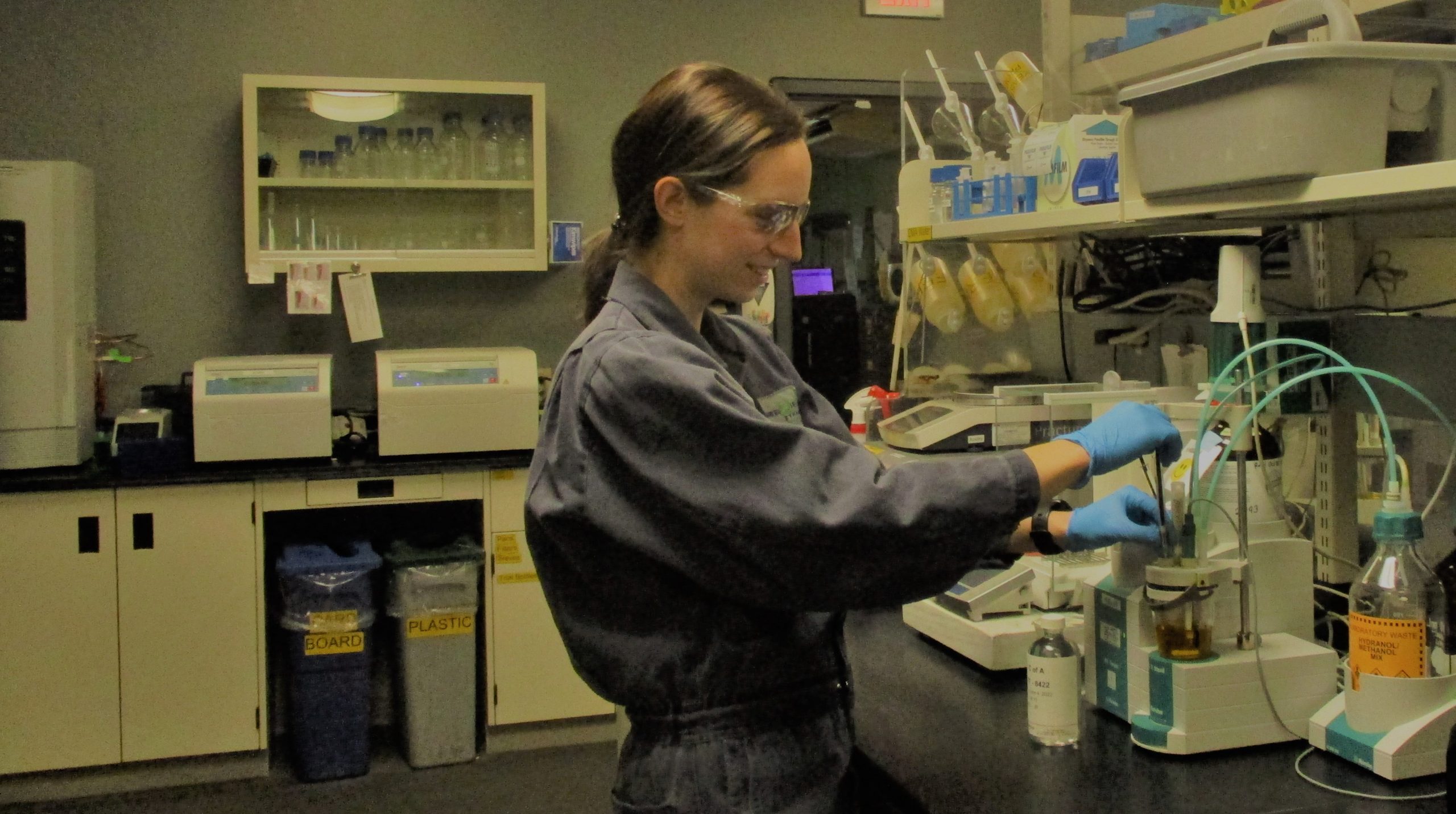

Testing for moisture on an alcohol sample

Do you have any advice for students interested in pursuing a similar path?

Take courses like Analytical Chemistry, Cell Biology, Biotechnology and Statistics, which are very relevant in the industry I work in. Analytical Chemistry gives experience and general knowledge of equipment as well as teaches how to calculate concentrations and do unit conversions. Knowledge of cell biology comes in handy when troubleshooting yeast in fermentation. Statistics is another very useful skill, even though people usually dislike learning it! Most experimental results require some sort of statistical analysis to prove significance. If you get good marks you can do research for professors in the summer and gain lab experience as well as learn good organizational skills. Anything that could set you apart from others would be an asset. Familiarity with Microsoft Office programs, especially Excel, is a very useful skill. Most of these courses are free online and can be done virtually.