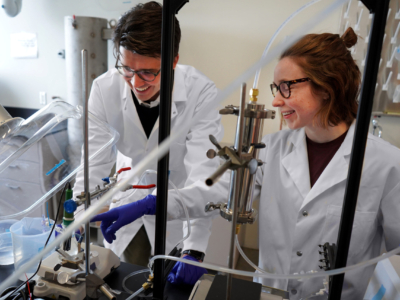

Musabbir Khan, Nick Stupich, Mark Klibanov and Amrita Sandhu are spending the summer developing their capstone project into a device with commercial potential. Photo: Luther Caverly

Taking a project from concept to commercial application is a long process. Tom Skinner is helping Carleton students get an early start.

Tom Skinner, MEng/72, has donated funds to run a two-year pilot project that will help engineering students begin to commercialize a fourth-year group project.

Capstone courses yield a constant stream of innovative projects. The challenge is capitalizing on that intellectual investment and moving it toward marketable solutions. By creating an intense summer fellowship program, a team of four students can refine and further develop a project with access to a technician and equipment.

“In grad school, or a fourth-year project, you finish up a project for grading and move on. I want students to have the chance to take it further—to take a term paper or project and develop it into something with a practical use,” he says.

Skinner himself did just that. He returned to university, working on his master’s degree initially as a part-time student, after working for Bell Northern Research, Nortel’s precursor.

“I needed to expand my engineering capability for what I wanted to do,” he says. “I never wanted to work for anybody. I wanted to be doing things for myself and making my own judgments. I wanted to test it out myself.”

After graduation, Skinner co-founded JSI Telecom, a manufacturer of equipment to intercept and analyze electronic transmissions. His ambition and love of the business led to more than 30 years of success. Now retired as chairman, Skinner can still be found in the Kanata office most days, acting as a corporate soundboard.

“I hope the commercialization summer fellowship helps develop the mindset that you’re not finished when you’ve solved the technical problems. You keep going,” Skinner says. “Solving problems is only a third of the way—it’s the start of a process to develop and bring a product to market.”

Taking MuscleMate farther

Polar, a heart-rate monitor manufacturer, turned a bulky medical device into a wireless, wearable personal fitness tool. Now a team of student inventors hopes to do the same for a muscle activity monitor.

As a tool for self-diagnosis or rehabilitation, the device, dubbed MuscleMate, could help people in physiotherapy to measure their progress, stroke victims to recover muscle function, body builders to target specific muscles, or amputees to control prosthetics.

“We proved the concept by using muscle signals to control a video game, but our product has potential beyond entertainment,” says team member Mark Klibanov.

“The commercial potential for the project is high, because the uses of the technology are so varied, and because there is no competing cost-effective solution in the marketplace yet,” says project supervisor Leonard MacEachern, associate professor of Electrical Engineering.

Amrita Sandhu and Mark Klibanov work on the proof-of-concept device that detects electrical signals generated by muscles in the wearer’s arm.

Klibanov, Musabbir Khan, Amrita Sandhu and Nick Stupich created MuscleMate for their fourth-year electrical engineering project. Worn like a blood-pressure cuff, MuscleMate uses electromyography (EMG) to detect tiny electrical signals generated by muscles in the wearer’s arm. Analog circuitry amplifies the signal and filters out atmospheric signals (such as from nearby lights). A microprocessor then converts the biological analog signal into a digital one, sending it wirelessly to a smartphone or computer. From there, gesture recognition software detects intensity and frequency of the impulses to determine strength and actions such as wrist turning. In the current video game application, relaxing and contracting the muscle bobs a helicopter over and under hazards.

After winning the Department of Electronics Best Presentation and Best Poster awards, the Carleton University IEEE Student Best Paper Award, and the Eastern Ontario Regional IEEE Student Best Paper Award, the MuscleMate team was chosen as the first recipient of the Carleton University Capstone Award. Thanks to the financial support of donor Tom Skinner, the Capstone Award will fund the MuscleMate team over the summer term to turn the project into a commercial venture.

“It would be hard to find a summer job where I could learn more than this,” says Stupich who, after investing about 40 hours a week into the project since January, is committed to see how far the team can take it. “The combination of working with hardware and software, of an electronics team on a biomedical project, was

appealing from the start. We’re making something genuinely cool.”

“My goal in conceptualizing capstone projects is to come up with projects that I wish I could have worked on for my final-year project!” says MacEachern. “Commercial potential and design economics are always a consideration, since we are doing real engineering design in these projects. This year the students have been given an excellent and truly amazing opportunity through the Capstone Award.”

For the team, the challenges over the summer include eliminating the sticky connections between the monitor and the user’s skin, and streamlining the design—“The cuff needs to be clean enough to wear without looking like a cyborg,” says Stupich.

“Basically, everything needs to be made smaller,” says Klibanov. “At this intermediate stage of development, we can use larger components to prove reliability, but to go to market with a useable, competitive product, we need to replace the circuit board with a microchip.”

For the students, preparing to graduate and take on the opportunity of a start-up company is exciting. With MuscleMate’s novel gesture recognition and a price tag that currently is 10 times less than portable EMG systems, the young entrepreneurs are well positioned to make a commercial breakthrough.

“We’ve been given the chance to really go for it over the next four months,” says Stupich. “We want to get MuscleMate to market.”