Silicon Photonics: The Next Generation of Computing Power

Ty Burke

Dusan Gostimirovic

Electronic computer chips power the phone in your pocket and the laptop on your desk. They manipulate electricity to transmit information, and are at the heart of a revolution in computing that has transformed virtually every aspect of daily life. But the computer chips of the future could be even more capable more than the ones use on today. Photonic computer chips transmit information using photons—particles of light—and are up to a thousand times faster than electronic chips. Photonic chips are more energy-efficient and can transmit data over longer distances without degradation in quality. But they are also pretty difficult to make—and to make work.

“It is still kind of a future-ish technology,” says Dusan Gostimirovic, who completed his PhD in silicon photonics at Carleton in 2019 and co-founded the company PreFab in early 2024.

“There are many potential applications, like quantum computing and machine learning, but the technology is not nearly as mature as electronic chips.”

From LEGO to Light: Rethinking Chip Design

Gostimirovic compares making an electronic chip to building with LEGO. Each chip consists of billions of tiny transistors—well-defined, tiny blocks that can be manufactured precisely at highly specialized facilities. But photonics, he says, is more like sculpting with clay. The chips use rounded waveguides that shepherd photons across the chip. It is difficult for chip makers to build these shapes at a microscopic scale, and any deviation from the intended design will reduce performance.

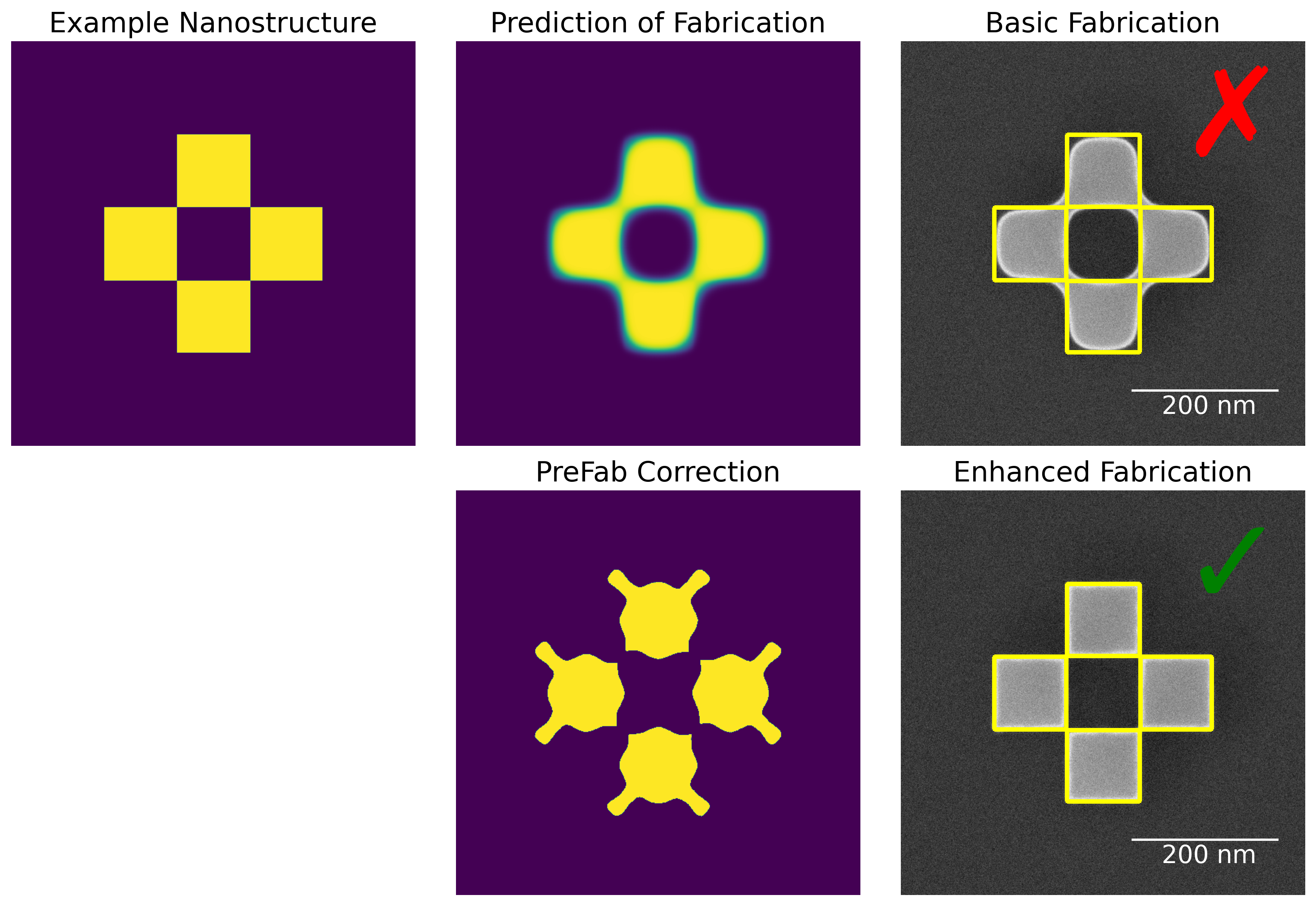

“It is hugely difficult to build these tiny components, such that they work as you expect them to,” Gostimirovic. “Any kind of structural deformation means the light interacts with the chip differently. And if you are using light to transmit data for communications, processing, sensing—anything really—the chip will operate differently than you expect it to, and it will always be worse. But if you can predict what the issue will be, you can modify the original design geometry, so that once the chip is manufactured, the photons will vary back to the original intended geometry.”

To recommend photonic chip designs, PreFab uses a computer vision AI algorithm that predicts the interactions between the photons and the waveguide structures, as well as how to modify those structures to correct for the distortions. One advantage of the approach is that it doesn’t require detailed knowledge of how a chip is manufactured. Chip makers are notoriously secretive, and closely guard their manufacturing processes as trade secrets. But PreFab’s algorithm relies on mathematical methods used in microelectronics for decades, with the AI component enabling a prediction of how to make the necessary adjustments. It is a software solution that tells designers what to build, without telling manufacturers how to build it.

“There is a recipe that goes into making a chip. They are extremely complex, with lots of money and secrecy involved,” says Gostimirovic. “When you spend months and many thousands of dollars making a chip, you want to know that it will not be a waste—that it actually works.”

Meeting the Demands of Entrepreneurship

PreFab’s early results have been promising, and the company has attracted funding from NSERC’s Ideas to Innovation and Lab to Market funding streams, as well as funding through McGill University, where Gostimirovic undertook post-doctoral research.

Still, the photonics space can be challenging for a startup. Most companies are focused on hardware, and require considerable funding. PreFab is a software solution to help those companies deal with manufacturing challenges. Developing software is easier than developing hardware, but it has challenges of its own. Gostimirovic notes that because there are few photonics software companies, there are few existing businesses that can serve as a model for PreFab.

“We think we have a good idea of where we want to go, but the exact path isn’t totally clear,” he says. “There are no examples of what Company A or Company B do in a particular circumstance. We are solving massive problems, and although there is a big opportunity, these are not easy problems. We think we have a great plan and a great technology, but it’s always difficult to move mountains.”

To navigate this uncertainty, Gostimirovic relies on his Carleton education, which he credits with giving him a broad-based education in photonics.

He did his PhD under the supervision of Professor Winnie Ye, who encouraged him to explore his research interests. This gave Gostimirovic a broad understanding of the field that is helping him meet the demands of entrepreneurship.

“Professor Ye guides her students, and lets you know where you should go and where you should not,” Gostimirovic says. “Early on, I had a passion for computing, but I didn’t know that much about photonics. From there, it evolved and I was able to explore many different areas. Often, a PhD student has a project already lined up for them when they arrive, but my PhD work was very open-ended, and I really cherish that. In the end, I think I learned more that way, and I had agency in what I should pursue. It gave me a real sense of ownership over my work.”