Students Tackle Real-World Issues Through Capstone & Studio Design Projects

Christine Scholman

Every June, a graduating class walks across the convocation stage degree in hand and a mind brimming with ideas.

For this year’s graduating Engineering and Design students, it wasn’t long ago that they presented and were evaluated on their fourth-year Capstone or studio design team projects. Groups solve tangible issues where creative problem-solving is required, such as rising Canadian housing prices, how to help wounds heal quicker and preventing dangerous crowd emergencies.

As the first university to adopt these team-style projects, Carleton’s Faculty of Engineering and Design (FED)’s capstones are an integral aspect of our undergraduate programs—and have been running for over 25 years.

The goal? To provide tangible solutions to real needs. Projects are specifically designed to foster an entrepreneurial spirit, critical thinking and an ongoing commitment and flexibility to solve real-world problems as a team. Many teams focus on serving a specific community or population in their work.

By applying and honing in on the knowledge and skills gained throughout their degree, students graduate with a final project they can be proud of.

A Glimpse Into the 2023-2024 Team Projects

As we get closer to convocation day, journey with us down memory lane for a snapshot of this year’s industry-disrupting capstone and studio design projects from graduating engineering and design students (schools and departments are listed in alphabetical order):

Architecture and Urbanism

Led by Arianna Conidi and Vanessa Jackson, Vanier Unifié is an innovative, transformative urban initiative reshaping the heart of Ottawa’s Vanier district at the Montreal Rd. and Place Dupuis junction.

The site plan aims to enrich the public space, repurpose an existing office building and incorporate a nonprofit residence for women transitioning from foster care and employs a trauma-informed design approach.

“Our project addresses significant societal challenges such as housing insecurity and trauma recovery, demonstrating our commitment to making a real difference in the community,” the students shared.

Townhouses and residential towers seamlessly integrate into the North side of the site within the Vanier Community Service Centre—making this Ottawa location a vibrant, unified and pedestrian-friendly community.

“We didn’t just aim to create aesthetically pleasing spaces; we sought to address these pressing issues and provide tangible solutions.”

Civil and Environmental Engineering

Canada faces a housing crisis, requiring urgent innovation to revitalize the Canadian dream of owning a home.

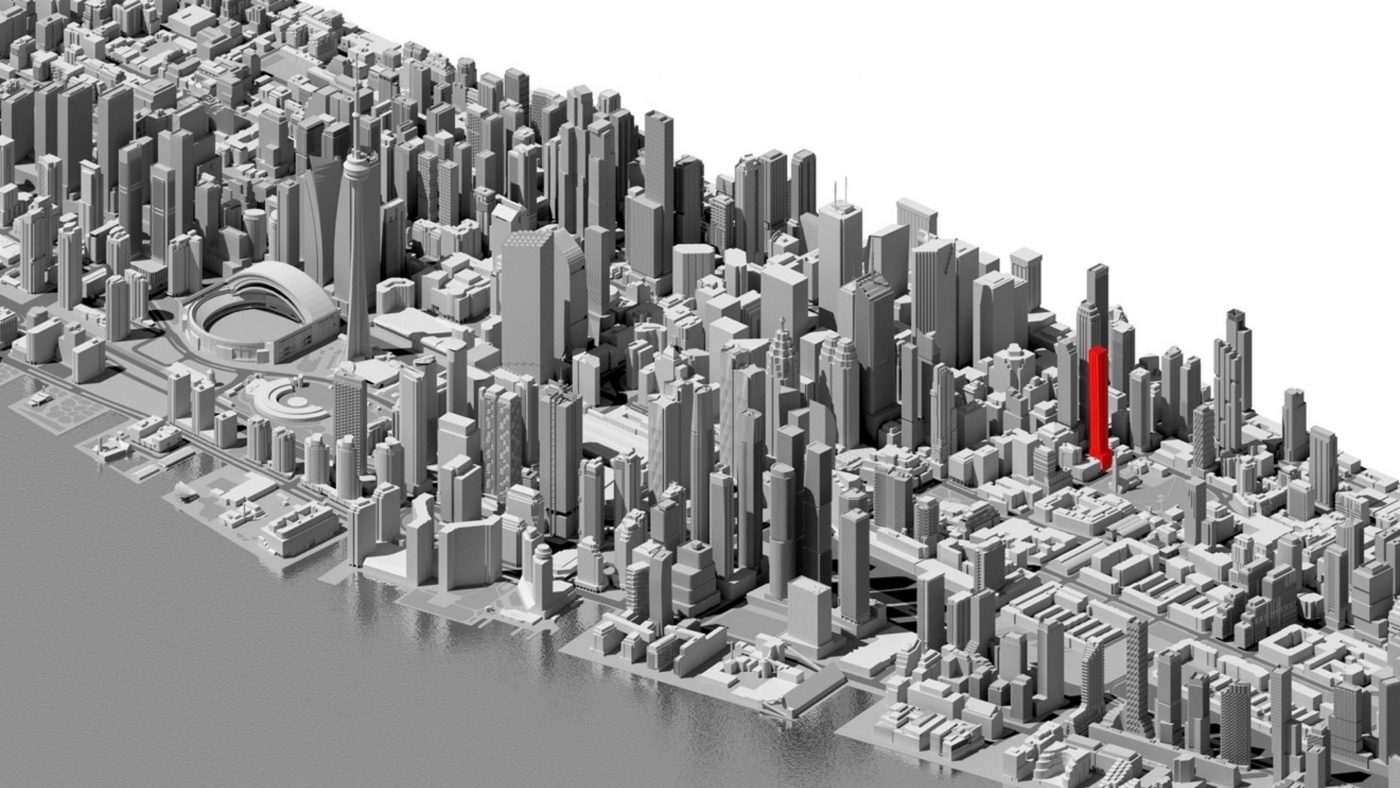

In response to this problem, 13 students in two capstone groups, WS4A and Horizon Builders, set out with an ambitious goal to design a 60-story high-rise with a footprint of half a hockey rink—in downtown Toronto. The two groups, led by Abbey Miller and Andrew Nguyen, titled the project: “Pencil Towers: the Future of the Urban Highrise”.

They designed one common architecture and two distinct structural buildings, with different materials to assess their relative building feasibility and general structural performance.

“We are most proud of our lateral analysis, comprised of a seismic and wind analysis, which was exceptionally difficult given the slender nature of the building,” the group commented. “Our lateral solution proposed a viable model that could be implemented to meet the expected structural demands.”

The team represented Carleton at the CSE annual conference in Niagara, Ontario in early June.

Electronics

What hardware is needed for a robot to be able to detect water and ice on the moon?

In collaboration with the Canadian Space Agency, the five-person student team, explored this challenge through the low-powered photonic communication system and 3-D printed robot, called the “PEEKBot Lunar Rover”.

The team, made up of Declan McCoy, Laurence Lemarche-Clic, Matthew Walsh, Nick Ficele and Vlad Artyshchuk, designed the hardware components (electronics, photonics, PCB etc) and use software coding for the control circuit.

Industrial Design

Could robots enhance human interaction, needs, safety and prevention in everyday scenarios such as hospitals, grocery stores or large events?

That’s what Kole Tromp, 4th year industrial design student, set out to design with CrowdShield, a robotic crowd management system.

At concerts, current crowd safety methods occur only after an incident has begun and rely on security guards to effectively communicate and either stop the concert or join together in a human chain to move people away from the incident. There are no preventative or robotic solutions available in the market.

That’s where Tromp’s robot design, in collaboration with Four DRobotics, provides elevated crowd safety through the detection and prevention of crowd crush events.

“What I am most proud of is the form of the robot providing balance between intimidation and comfort,” said Tromp.

“The design language of its “chest out shoulders back” pose, the subtle floating effect due to the darkened lower section, the intimidating “eye” on the front which communicates the surveillance aspect of the robot, and the sleek smooth looks bringing back some comfort to the shape.”

Information Technology

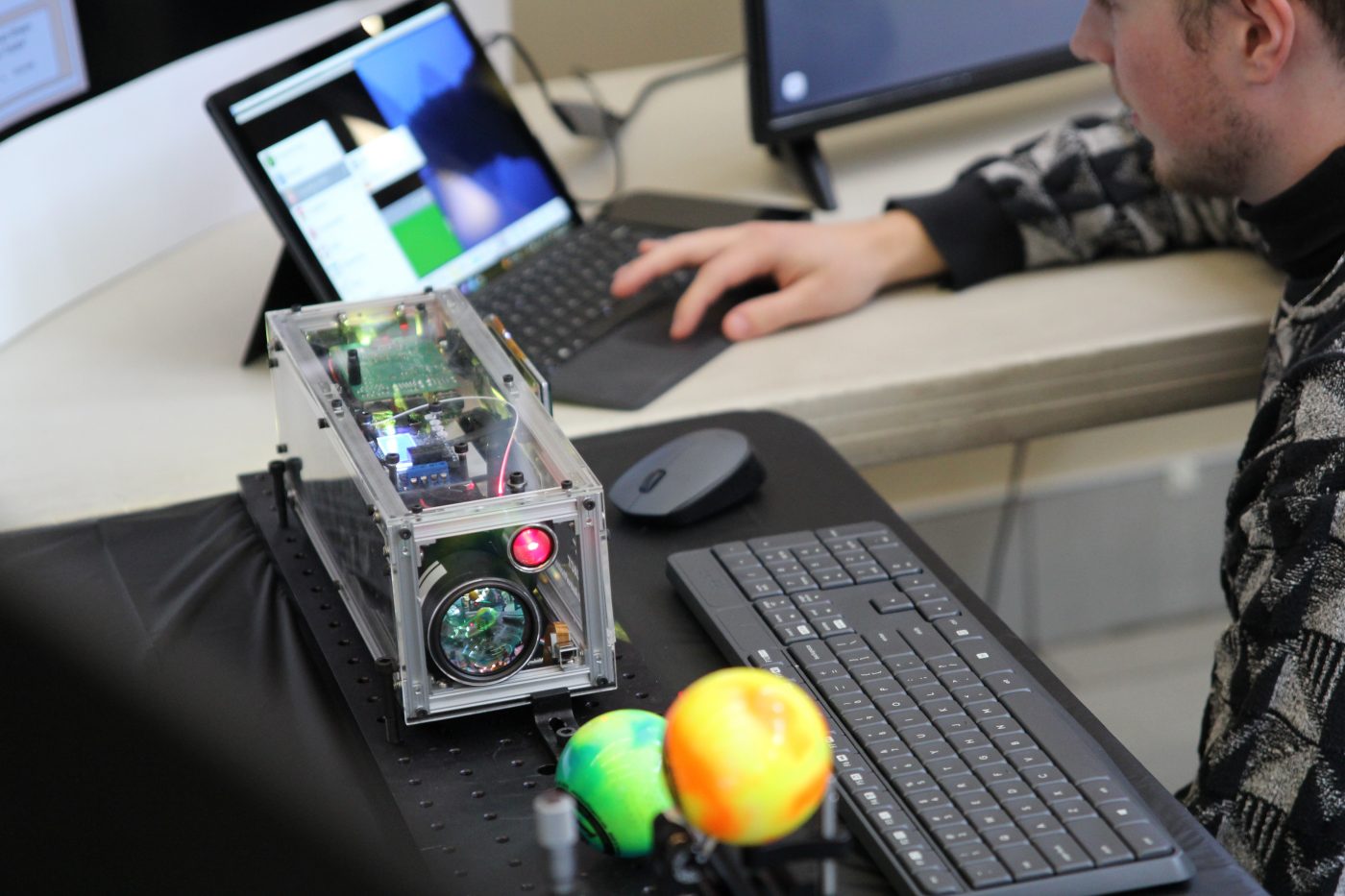

Led by Tyler Deloughery, Clayton Lauzon and Haydn Sims, the Tesaract satellite model is a pathfinder and cutting-edge development towards more cost-effective, space-based observation of oxygen atmospheres and space exploration.

The model detects light transmission through the photonic chip in the visual and infrared bands to detect a signal. The team used the CubeSat, a low-cost, space-based platform designed at the National Research Council Canada. It is mass-producible, smaller and lighter than alternatives on the market – which makes it more accessible to a wider range of companies and scientists.

Up until now, however, little research has been done investigating pairing CubeSats with photonic integrated circuit instrumentation:

“We are the first group to place a Photonic Integrated Circuit (PIC) into the CubeSat platform,” said Deloughery. “Leveraging the precision and low weight provided by the PIC along with the small size and low weight of the CubeSat platform, we prove the viability of low-cost launches using these systems.”

Mechanical and Aerospace Engineering

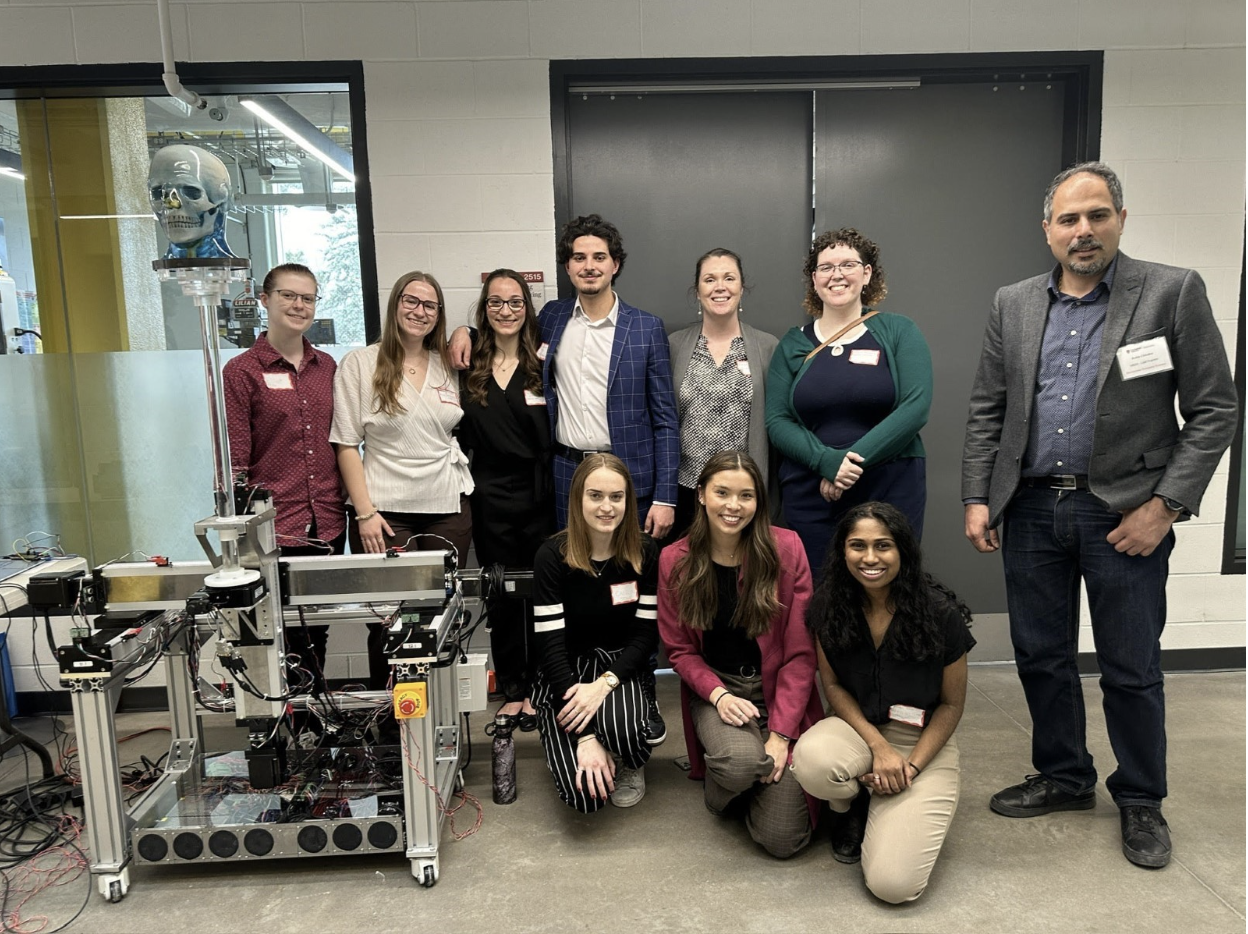

In collaboration with Health Canada, the Mechatronics Dosimetry System (MEDS) capstone is a project aimed at advancing x-ray device characterization testing capabilities within Health Canada’s Consumer and Clinical Radiation Protection Bureau (CCRPB).

By leveraging mechatronics, this project integrates mechanical, electrical and software components to create a testing platform to precisely and efficiently measure radiation doses.

In its third year of development, the project’s 2023-2024 team goals were to implement safety features, optimize the design and enhance user experience.

This year’s team, which included Hannah Samson, Alia Nichol, Vasuki Siva, Melissa Figueroa, Sophia Matricardi, Caitlyn Stowe, Alessandro Mafrici and Eliot Beatty, went above and beyond:

“Our team is most proud of successfully delivering a fully functional system to Health Canada,” said Nichol, the team lead. “It was an ambitious goal for the year, but we achieved it. We provided Health Canada with a detailed user manual to facilitate the use of the MEDS system and dosimetry testing.”

“I am personally very proud of my team’s persistence. Despite several challenges along the way, we did an excellent job of overcoming them and delivering a final product.”

Systems and Computer Engineering

In tissue engineering, one of the biggest challenges is being able to simulate the conditions cells find in our bodies.

Biochemical and mechanical cues are important elements in organs and tissues, which cause the cells to behave in certain ways (e.g. heal injuries, migrate from one site to another, etc). For example, the lungs inflate and deflate as we breathe.

So, how can we simulate this movement, tissue stretching and contraction in the lab?

In this capstone project, a team of students developed a low-cost stretch chamber able to deform 3D bio-printed tissues and record biomechanical information from the sample (e.g. deformation coefficient) and allow the user to control parameters such as frequency of deformation and intensity.

The Future is Bright

To our graduating class of 2024, we’re cheering you on as you step into new opportunities and career paths. With ideas and experience in hand, these capstone and studio design projects are proof of how you already challenge what’s possible to innovate in incredible, felt ways that create a better future for all.